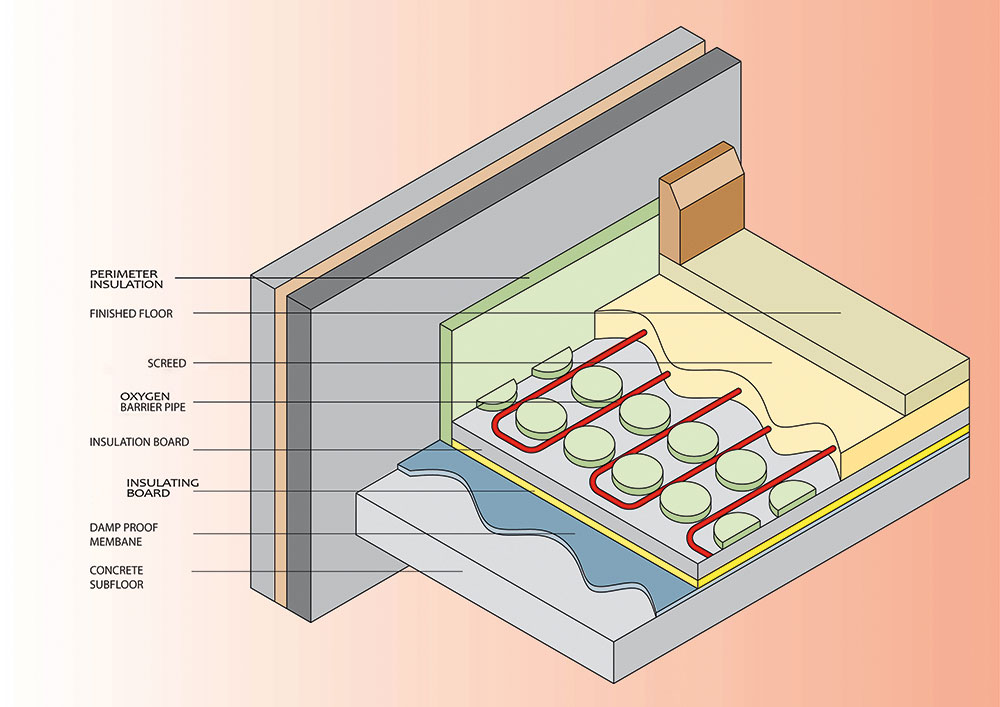

The difficulty of course is that if the moisture barrier is compromised in any way moisture from the slab beneath can still damage the flooring or finish.

Moisture control sub flooring.

Ideally it should be between 7 and 9.

Cooler temperatures in basements and crawlspaces create unique humidity control challenges.

Sub floor moisture testing is required to comply with astm regulations and it s often necessary to follow specific testing procedures to comply with your flooring warranty.

All types of subflooring should have some sort of vapor retarder barrier installed to block moisture from seeping up from the subflooring into your new hardwood flooring.

Our subflooring systems can be used with many types of flooring including hardwood particleboard laminate carpeting and vinyl.

While measuring your sub floor moisture levels may seem like a complicated and time consuming addition to your flooring installation process don t be tempted to skip it to speed up the process.

First test the moisture level of the subfloor.

Excess moisture encourages mold growth on wood and any organic material in your basement or crawlspace.

For floating floors manufacturers often recommend installing a moisture barrier between the subfloor and the floating floor to prevent moisture intrusion.

In general 12 moisture or above is too wet to install flooring.

Residential subfloor moisture barriers are a must for finished basements located in flood plains foothills rainy towns and other high moisture areas.

How to install vinyl plank flooring as a beginner.

Take the readings in at least 20 spots per 1 000 square feet of flooring and average the results.

Grout or cementitious bonds.

Often the only way to maintain the epa s recommended humidity levels for homes of 50 rh or less is by running a high capacity high efficiency dehumidifier.